VP5 Vibration Data Collector

VP5 is a 4-channel portable vibration data collector and handheld vibration analyzer powered by Microsoft Windows CE and state-of-the-art DSP technology. VP5’s rugged housing is made from a high tech, dual-material injection process, consisting of hard ABS plastic (black) and soft TPR plastic (orange). VP5 also has rubber seals for IP65 protection in extreme weather and harsh environments. Equipped with VGA resolution color touch screen, VP5 brings you a state-of-the-art experience with in-field portable vibration analyzers.

- Data Collection and Recording

- Rotor Dynamic Balancing

- Computed Order Tracking

- Data Recorder

- Bump Test

- ODS test

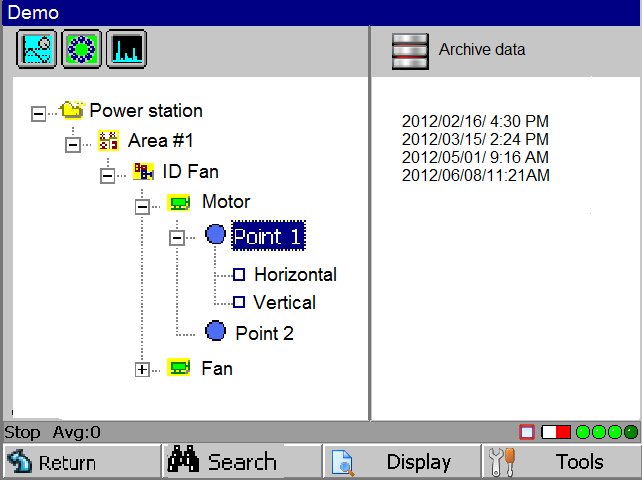

Route-Based Data Acquisition

Combined with the powerful computer-based iSee predictive maintenance software, the field-proven VP5 portable vibration data collector is your best choice for route-based data acquisition.

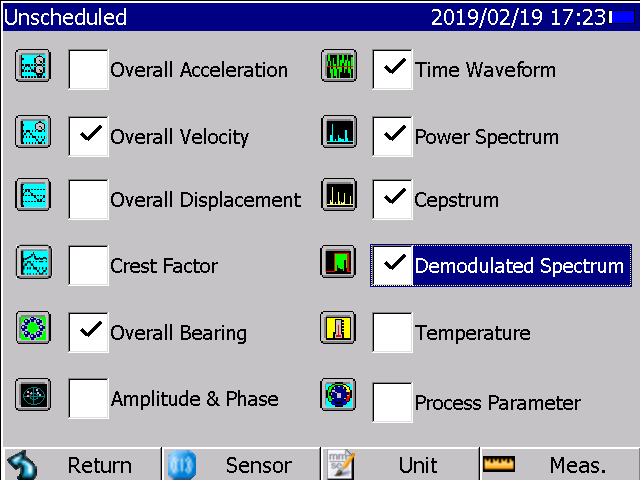

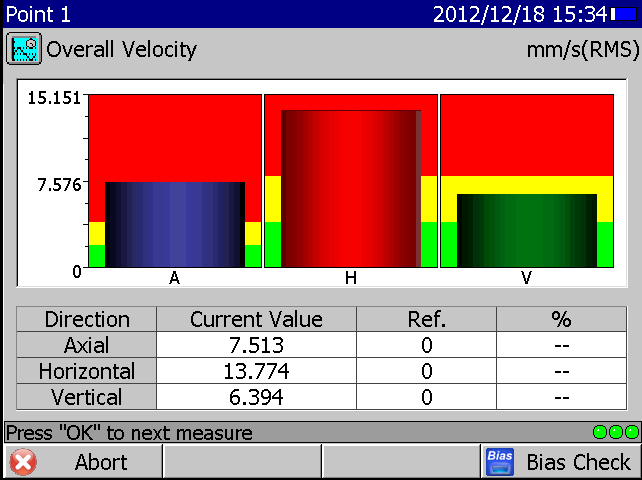

- Simultaneous tri-axial measurements (x,y,z axes) save hours in the field

- Measures bearing fault signal via true peak detection on a high-pass filtered time waveform

- Sensitive and accurate readings of early-stage of bearing damage allow the user to track bearing damage development via a trending analysis feature in iSee predictive maintenance software

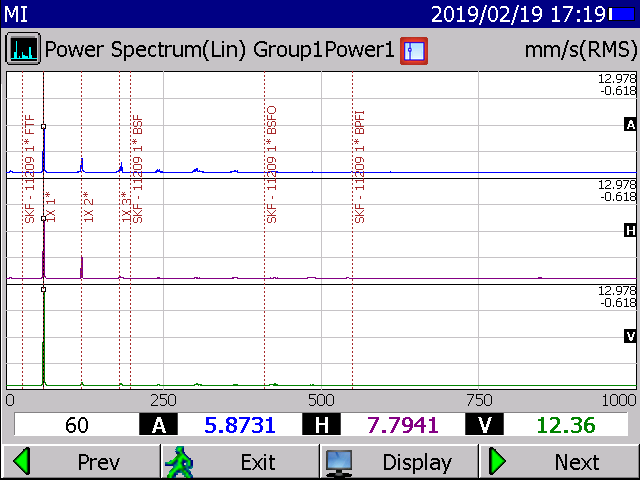

- Envelope spectrum measurement for confirming bearing damage is a standard feature

- Temperature and other process parameter measurements are supported

Bump Test Module

VP5’s optional and powerful Bump Test Module allows you to measure a structure’s frequency response frequency (FRF), coherence, and cross power spectrum functions. This useful vibration analysis software module helps investigate the resonance of a machine, enact structural reinforcement and reduce the vibration levels of a machine running at its resonance zone. Test data can be imported to a 3rd party software, such as ME’Scope, for further modal analysis to derive its modal shapes, natural frequencies and damping values.

Note: VP5’s bump test features are very similar to Benstone’s impaq Elite portable vibration analyzer. See demonstration video above.

ODS Test module

VP5’s optional Operational Deflection Shape (ODS) module allows you to conduct a measurement on a running machine and measure its FRF, coherence, and cross power spectrum functions. With the reference vibration sensor connected to channel 1 and a triaxial vibration sensor connected to channels 2, 3, and 4, the VP5 vibration data collector saves you time in the field with real-time, 4-channel measurements. By importing the test data to a 3rd party software, like ME’Scope, you can easily derive the operational deflection shapes of your machines at certain running speeds and use this information for structural reinforcement.

Computed Order Tracking Module

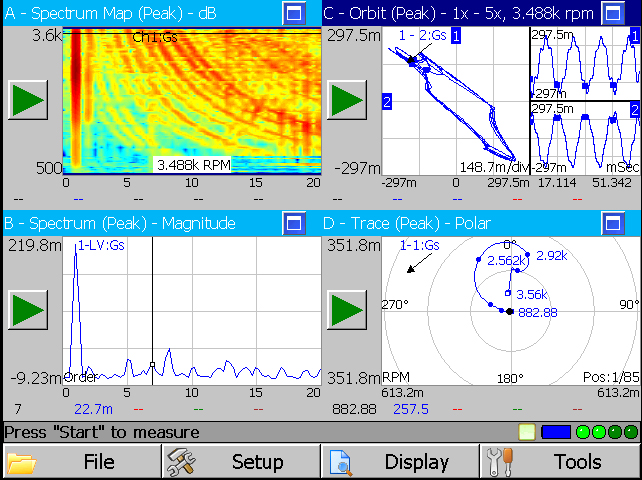

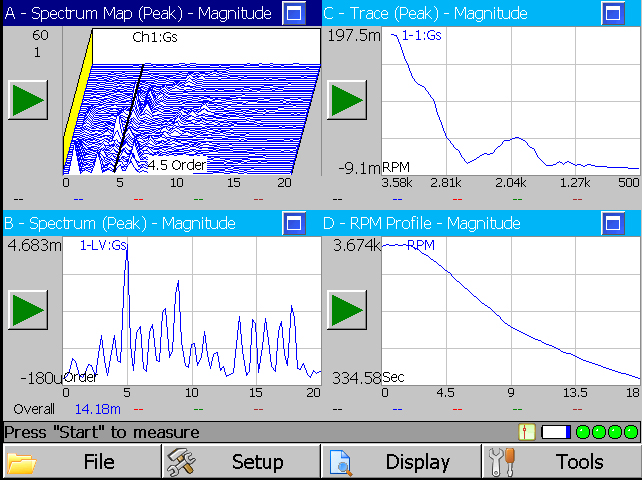

The optional Computed Order Tracking module is designed to analyze the sound or vibration signals of varying-speed machines. Typical applications for this capability are NVH (Noise, Vibration, Harshness) testing of vehicles and advanced vibration analysis of turbine machines. It accurately calculates the order spectrum, order traces, filtered or unfiltered orbits, gap reading and the centerline of a shaft during a start-up or coast-down process. The VP5 Vibration Data Collector’s order tracking algorithm performs digital re-sampling of the measured signal for ensure data accuracy. The order spectrum data can be displayed on a waterfall plot or intensity map. Cut a slice or a trace of data from the waterfall plot and then examine the individual traces. As shown in the figure below, the user can enter the geometric position(s) of the vibration sensor(s) to create a plot to display orbit and shaft centerline motion, which relates to the realistic behavior of a turbine machine.

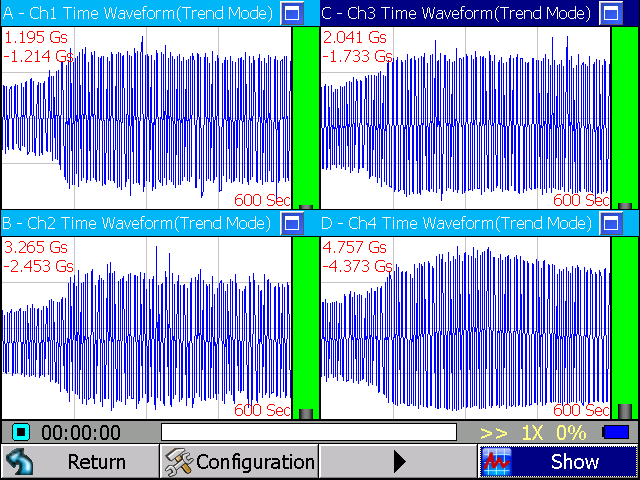

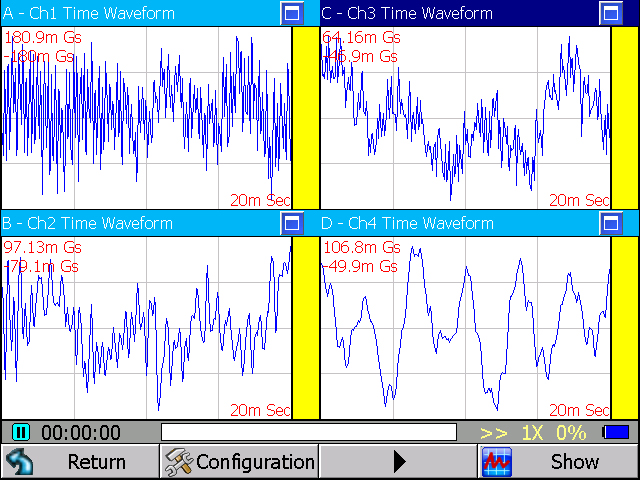

Raw Data Recorder Module

The optional Raw Data Recorder Module directly records raw time data to the built-in compact flash card. For example, a 1 GB file will contain approximately three hours of continuous data with four channels recording at 2 kHz bandwidth. Benstone’s computer-based Novian Dynamic Signal Analyzer Software allows for playback and post-processing of raw data recorder files, such as FFT, order tracking or octave analysis.

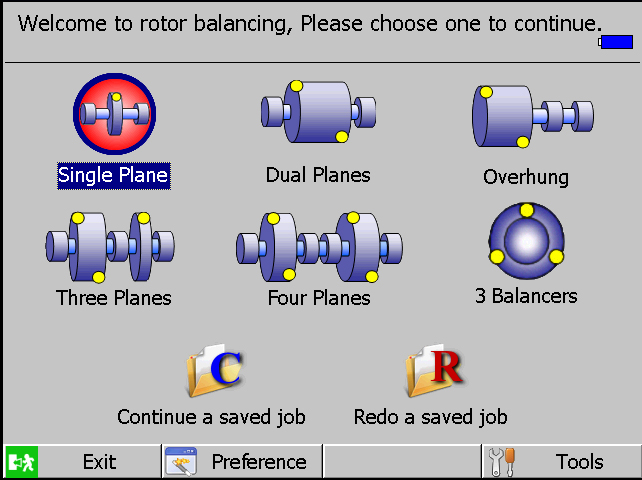

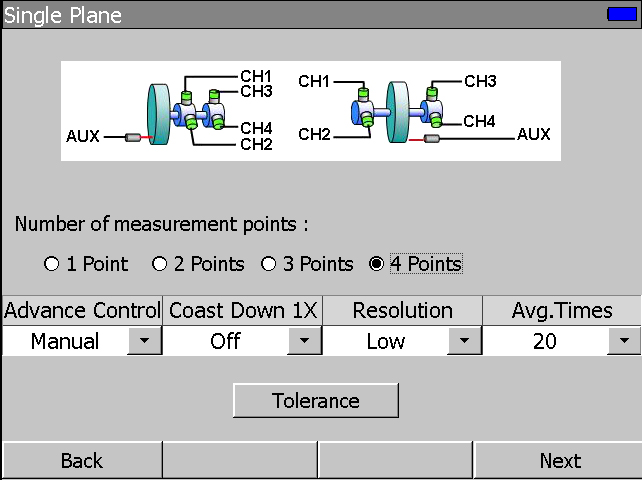

Rotor Balancing module

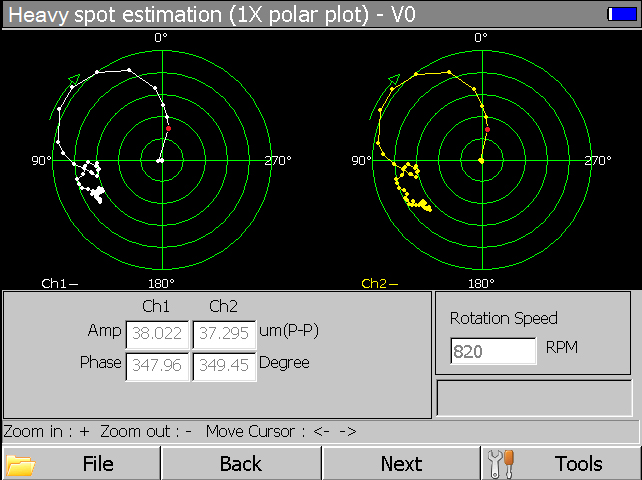

The optional Rotor Balancing Module is a field balancing software package for rotating machines that utilizes industry-leading rotor balancing techniques: single-plane, dual-plane, overhung dual-plane, 3-plane, 4-plane, and 3-weights balancing. This advanced software simplifies field balancing of machines with a very high level of accuracy. Now with multiple-point balancing, vibration is minimized in BOTH horizontal and vertical directions at the same time. By enabling coast-down measurements for 1X vibration, the heavy spot is identified correctly with only one measurement, saving you time and money by eliminating the use of trial weights. It also eliminates safety concerns from placing the trial weights in the wrong location.

Demonstration video: How to locate the heavy spot before the trial weight is added.